Decommissioning Update: A Visit to Fukushima Daiichi

Society- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Changing Shape of the Nuclear Reactor Building

I visited Fukushima Daiichi Nuclear Power Station in late October 2024. Soon after the 2011 nuclear accident, I was the head of a Japanese newspaper team reporting on the situation, but this was the first time I had entered the grounds of the facility. Measures are in place at the site to prevent the dispersal of radioactive material. The building and parts of the site are still designated as red or yellow zones, where full-face masks and full-body protective clothing are required due to high radiation levels. But most of the site is a green zone, where protective clothing is unnecessary. For reporting, we were only required to wear helmets, regular masks, and work gloves.

Workers at Fukushima Daiichi wearing full-body protective clothing on October 21, 2024. Such measures are still mandatory for entering areas with high radiation levels. (© Hashino Yukinori)

According to Tokyo Electric Power Company, the site had received 7,594 external observers in fiscal 2024 by the end of August, not counting members of the media. This compares with 18,516 in fiscal 2023, and is around 20 times more than the 913 visitors in fiscal 2011. Visitor numbers declined during the COVID-19 pandemic, but are on the rise once more. Immediately after the accident, TEPCO restricted entry to the site due to the risks posed by high levels of radiation and debris, but now they are encouraging observer visits to better inform people about the progress of the decommissioning work, including the release of treated water into the ocean. There is no record of the number of media visitors received, but a TEPCO official advised us that it is increasing, including members of foreign media organizations.

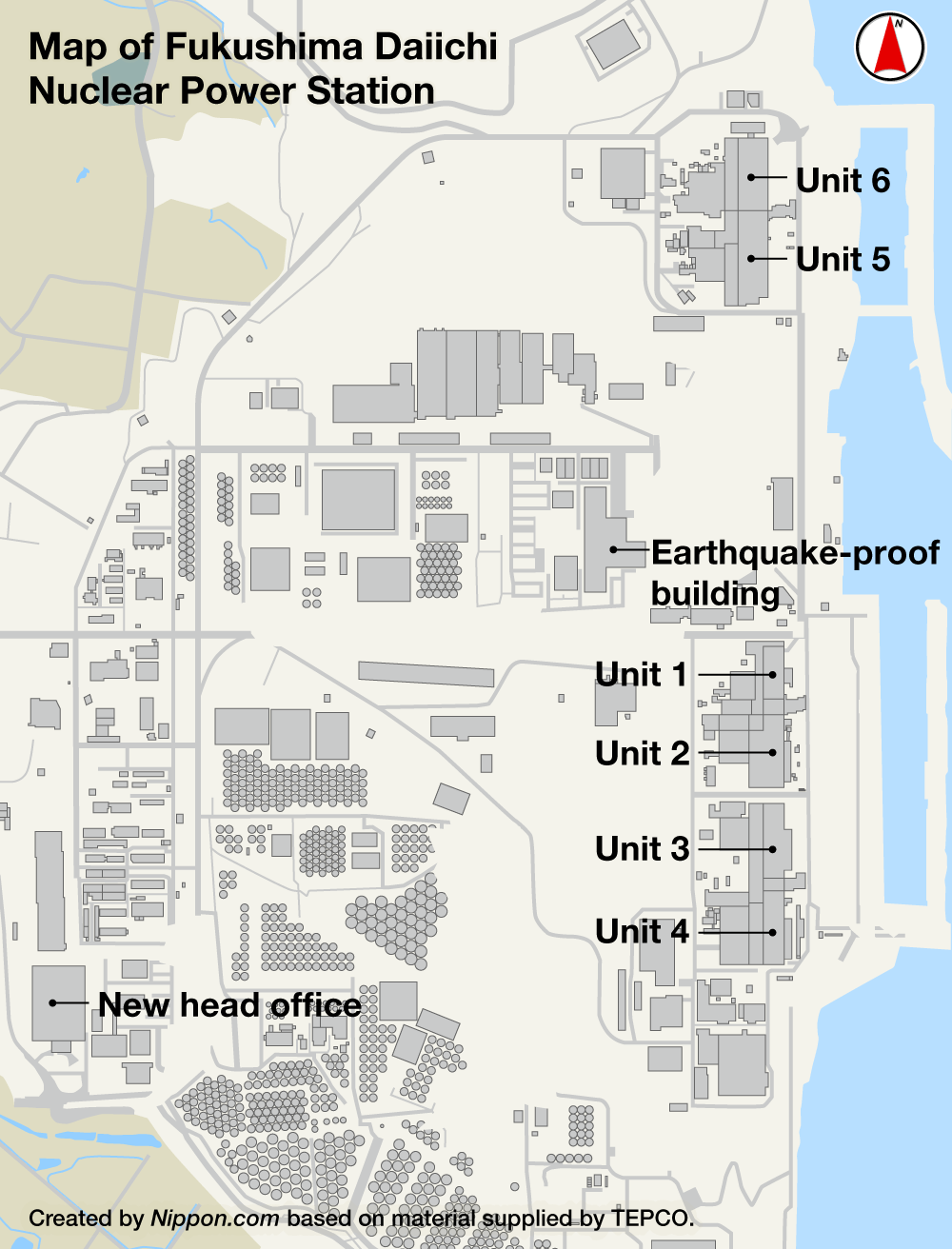

From a nearby hilltop, we could view the reactor building from above, and it was easy to see that the work on units one to four of the power plant is at different stages. The hydrogen explosion at Unit One tore apart its steel frame, and it still is the clearest indication of the severity of the accident. Its internal spent fuel pool still contains 392 nuclear fuel units, but the structural debris and large crane still remain, impeding cleanup work. Construction of covers enclosing the buildings to prevent dispersal of radioactive material during the operation is progressing in other areas.

A dome-shaped roof built over Unit Three of the reactor for the removal of spent nuclear fuel at TEPCO’s Fukushima Daiichi Nuclear Power Station. (© Hashino Yukinori)

Unit Two, which suffered a meltdown but did not explode, is surrounded by steel framework to facilitate work on the unit. The exterior of Unit Three has a shining, silver-domed roof to protect equipment used for removal of spent fuel. Already, 566 units have been removed. Unit Four, which was undergoing regular maintenance at the time of the accident, did not melt down, but suffered an explosion due to hydrogen entering through pipelines from Unit Three. It is mostly hidden by structures built over it to enable the removal of its 1,535 fuel units.

Radiation Building Up

From the windows of the microbus that transported us around the enormous site, we saw storage tanks filled with decontaminated water and areas crammed with containers of waste matter. Rusted, giant turbines, previously used to generate electricity, sit neglected. Most of the debris has been removed from where it fell during the disaster, but water tanks and other facilities that were badly damaged by tsunami still testify to the accident. Part of the shield machine used to excavate the tunnel to carry treated wastewater to the ocean has been preserved as a memento on the observation deck for units five and six.

Tanks used to temporarily store treated wastewater at Fukushima Daiichi immediately after the accident. They are no longer required now that permanent tanks have been installed. (© Hashino Yukinori)

A vehicle used in cooling spent fuel pools in the reactor buildings immediately after the accident. It was nicknamed kirin (giraffe) and was used to spray water from high up into the structures. (© Hashino Yukinori)

A part of the shield machine used to excavate the undersea tunnel used to carry treated wastewater to the ocean. (© Hashino Yukinori)

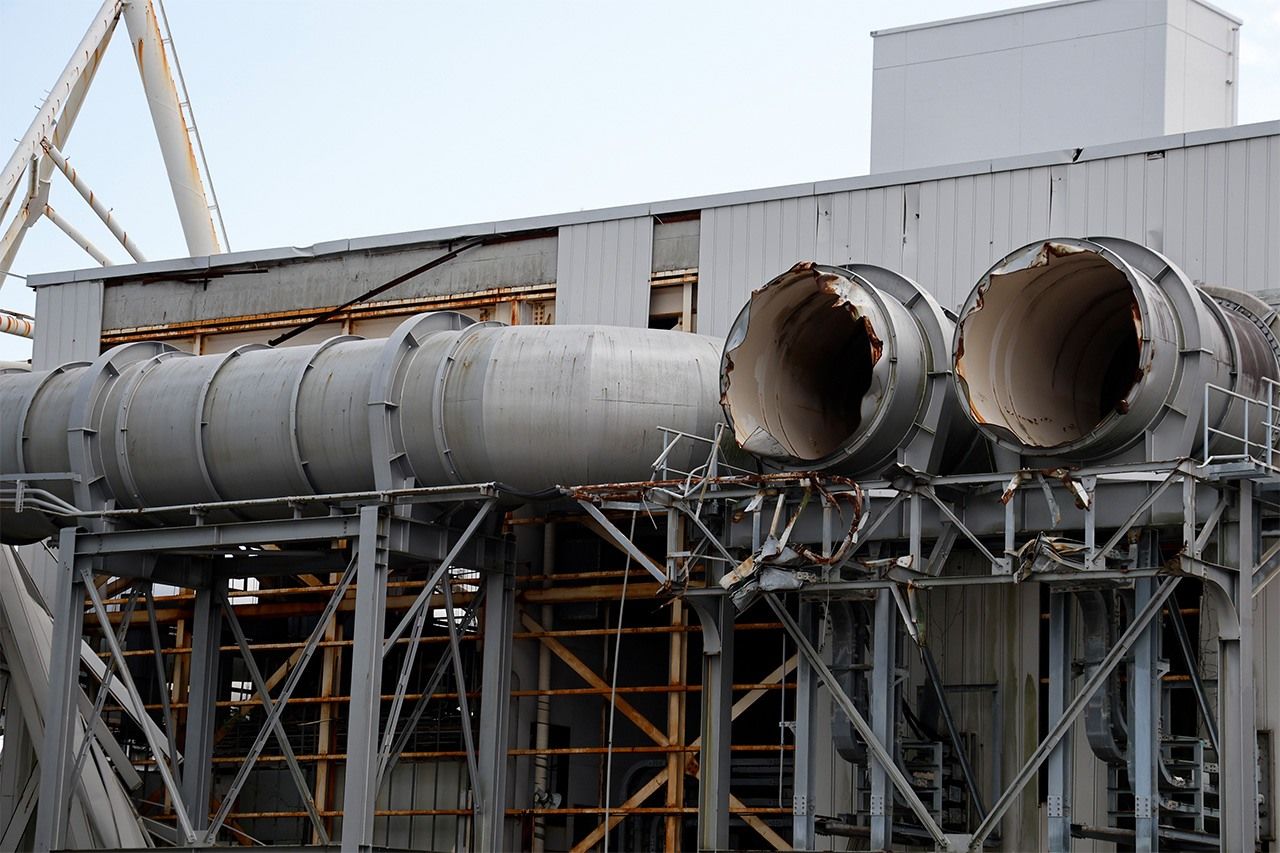

We alighted from the bus and walked from the sea side of Unit Four to the land side. As we proceeded, I looked up at the buildings and structures we had seen from the lookout: giant duct pipes, hacked open, were particularly ugly. Before, they connected units one to four with exhaust towers, but they obstructed decommissioning work, and were cut open. Green chemical residue is still visible on Unit Three, where it was applied to prevent radioactive material stuck to the structure from blowing away.

Enormous exhaust ducts cut off to allow access for the decommissioning work. They once connected units one to four with exhaust towers. (© Hashino Yukinori)

The chemicals sprayed on Unit Three to prevent dispersal of radioactive material stuck to the structure are still visible. (© Hashino Yukinori)

North of Unit Three, the level of radiation rises as we approach Unit Two. I was concerned by the reading on my personal dosimeter attached to my vest. Unit Two is undergoing work to remove nuclear fuel debris comprised of fuel melted in the accident mixed with structural material. Workers near the delivery exit are completely covered by protective clothing.

We head back towards the sea between Units Two and Three, and the air dosimeter reading increases to 240 microsieverts per hour. Before we can look closely at the damage to the building, our guide hurries us along. According to the guide, the reading was over 300 microsieverts a few years ago, but it is still at a concerning level.

The level of radiation increased between Units Two and Three to 240 microsieverts per hour on October 21, 2024. (© Hashino Yukinori)

On the ocean side we inspect the one-kilometer-long seawall, completed in March 2024 to protect against tsunami. The concrete block wall ranges from 13.5 meters to 16 meters in height. It is designed to provide protection against even a major tsunami triggered by a quake along the Japan Trench, whose occurrence is considered possible at any time. TEPCO believes that the wall will reduce the risk of environmental pollution caused by leakage of contaminated wastewater.

The seawall constructed for tsunami protection is approximately a kilometer long. (© Hashino Yukinori)

Two-fold Challenge of Water and Debris

On November 7, TEPCO removed a piece of debris some five millimeters across from Unit Two’s containment vessel using specialized equipment. This success will assist investigations into a full-scale debris removal process. TEPCO estimates that the vessels in Units One to Three contain approximately 880 tons of highly radioactive debris, which is considered the greatest challenge in the decommissioning. According to Kimoto Takahiro, deputy site superintendent of the Decontamination and Decommissioning Communication Center, “We have finally made the first step in the decommissioning process, more than thirteen years after the accident. But the work has only just begun.”

Removal of fuel debris from the containment vessel inside Unit Two using specialized equipment. The pincer-like object is holding debris. October 30, 2024. (Courtesy TEPCO)

Work is making definite progress in all areas, but there is still no concrete solution to dealing with the decontaminated water: a major obstacle in the decommissioning. Some 60 tons of underground water and precipitation flows into the nuclear reactor building daily. In addition, water is used continuously to cool the nuclear reactors, producing 80 tons of contaminated water each day.

TEPCO uses an Advanced Liquid Processing System to treat the contaminated water, which is then stored in tanks on site. The company began releasing water into the ocean in August 2023, and had done so 10 times up to November 5, 2024, with a total 78,285 tons of water released. The most dangerous contaminants have all been removed, but the water still contains tritium, a hydrogen isotope that is found naturally and is difficult to extract from water. Consequently, a total of approximately 14.8 trillion becquerels of tritium has also been released, but TEPCO is continuously monitoring the surrounding ocean water and states that there are no abnormalities.

It is expected to take 30 years to release all of the treated wastewater currently in storage. It is also difficult to prevent contamination of water that continues to enter the site, meaning that this amount will keep increasing. Unless the number of tanks being used for processing and storing water can be reduced, the space they occupy cannot be used for installation of storage facilities needed for removal of debris, impacting the overall decommissioning plan.

Dealing with water and debris poses a twofold challenge to the work. Kimoto says that the volume of contaminated water remains an issue. “If we can control the increase in volume, we can set a firm goal for the decommissioning plan.”

Looking out to the Pacific Ocean from Fukushima Daiichi Nuclear Power Station. The outlet for the pipe carrying treated wastewater is approximately one kilometer out to sea. (© Hashino Yukinori)

(Originally published in Japanese. Banner photo: The framework of Unit One of Fukushima Daiichi Nuclear Power Station, in the foreground, was exposed by hydrogen explosion. The cylindrical dome that can be seen is Unit Three. TEPCO Fukushima Daiichi Nuclear Power Station, October 21, 2024. © Hashino Yukinori of Nippon.com.)